How We Helped Fluid Bring the Beyondex Mod to Life

2026-01-04 · Daniel Liu

From two failed attempts to 300 production units in weeks

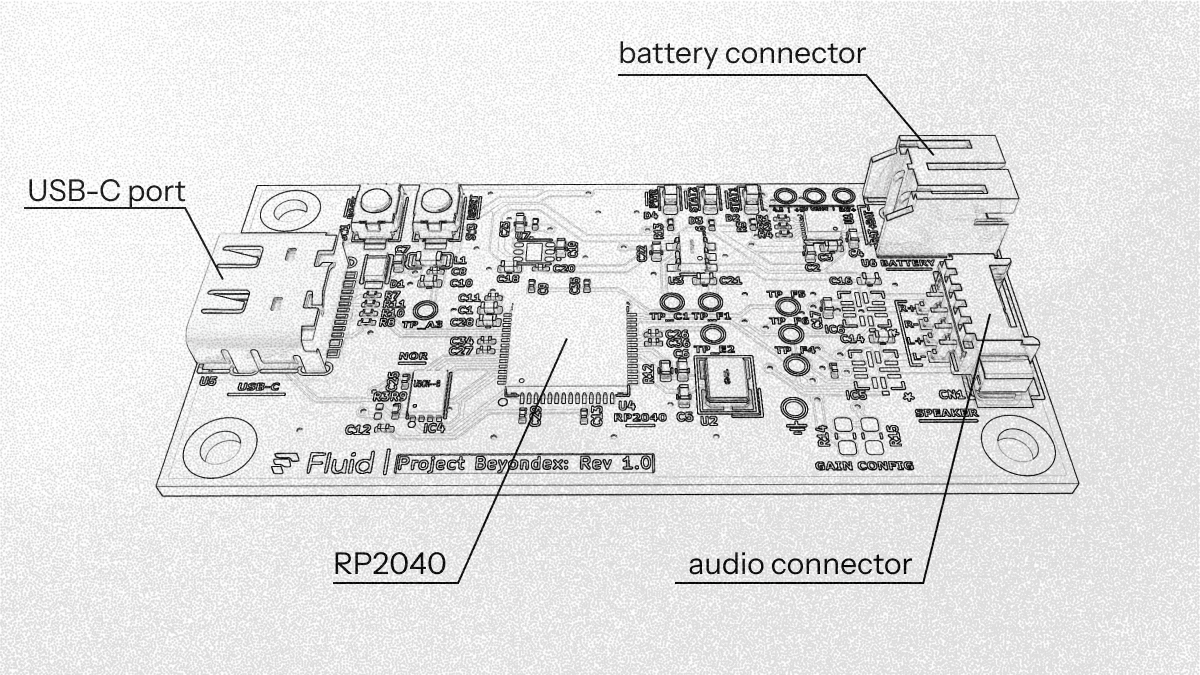

Beyondex is a custom hardware mod that brings Valve Index audio to the Bigscreen Beyond VR headset. It combines a Raspberry Pi 2040 based DAC, smart battery management, and tight mechanical integration into a clean kit that feels native rather than hacked together.

When Fluid came to us, they had already tried twice to get the electronics working. Pre-orders were coming in, but the hardware still was not shippable. We delivered a production ready design in under a week, and helped scale from prototype to 300+ units.

Interested in getting your own Beyondex mod? Join the waitlist to be notified when the next batch is available.

This is how we did it, and why our approach works when contractor platforms fall short.

The Problem: Two Failed Attempts

Fluid had already hired two different designers before reaching out to us. Both attempts left the project blocked.

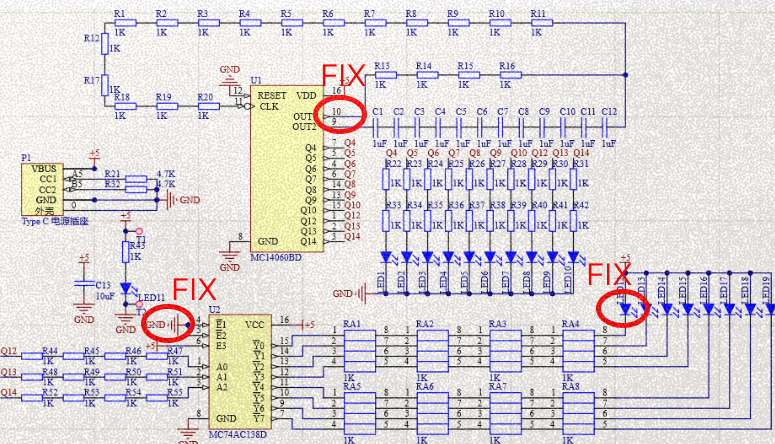

The first attempt came from Fiverr. On paper, the board looked reasonable. In practice, it failed basic tasks. The RP2040 would not reliably enter BOOTSEL mode, so firmware could not be flashed over USB. The designer added extra buttons that served no real purpose and chose ultra bright LEDs that were unpleasant in a VR headset. When the client asked for design files to iterate, the engineer refused to provide them.

The second attempt got closer but still missed fundamentals. The board size was not constrained by the 3D enclosure. Connector placement did not match the mechanical design. The power management approach using an IP5310 chip did not clearly handle how to pull 2+ amps from a small battery while respecting USB 2.0's 500 mA limit. The client was left with broken boot flows, overcomplicated hardware, and an uneasy feeling that the power path was not actually under control.

With pre-orders already live, the project was stuck. The hardware did not feel shippable, and there was no clear path forward.

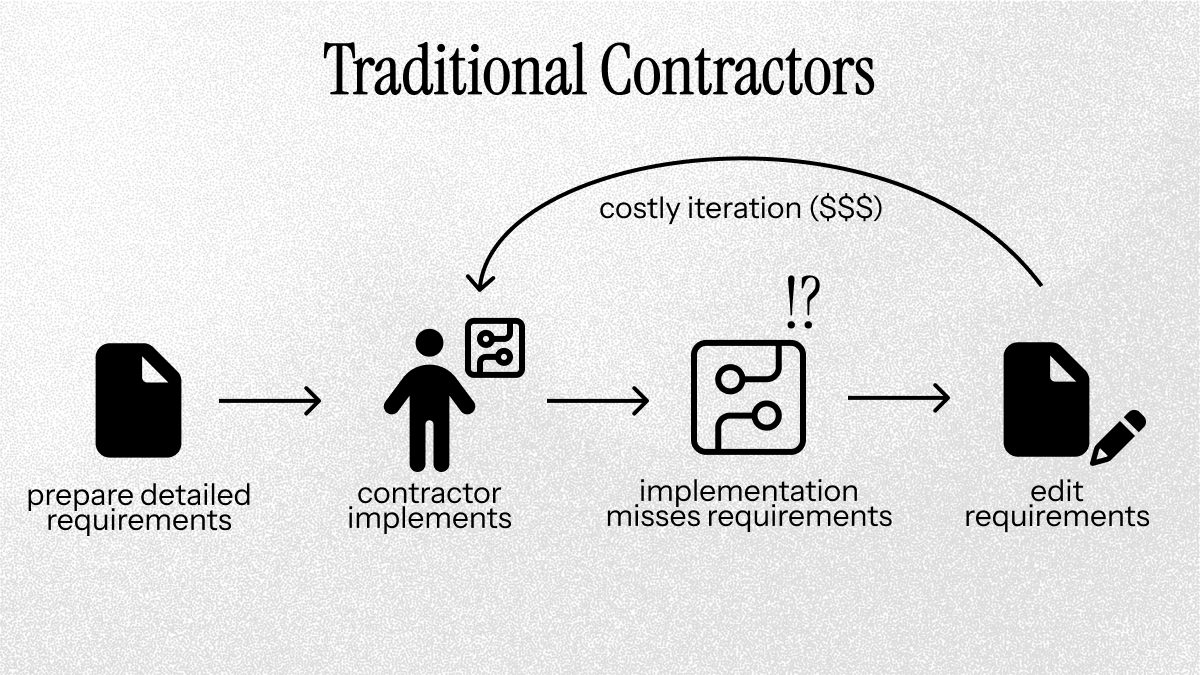

Why Contractor Platforms Often Fall Short

Hiring from platforms like Fiverr or Upwork can look cost effective. For straightforward tasks with clear requirements, that model works fine.

But hardware is rarely straightforward. The Beyondex story shows what happens when requirements are fuzzy. The first designer delivered unusable firmware workflows and awkward UI because the problem was never clearly defined. The second got closer but still missed mechanical and power constraints.

The issue is not that contractors lack skills. The issue is that transactional remote work puts all the burden of specification on you. If you do not spell out every edge case, every mechanical dimension, every user interaction, and every electrical limit in advance, the designer will fill gaps with guesses. Sometimes those guesses are right. Often they are not, and you only discover the mismatch when broken prototypes arrive.

Writing a truly complete spec requires deep hardware knowledge. If you already knew which components to use, how the power path should work, and which connectors fit your enclosure, you would not need outside help. Contractor platforms assume you can do that upfront work perfectly, which is unrealistic for most teams launching their first or second hardware product.

Hardware projects carry massive context. Even when you think you have captured everything in a kickoff meeting, there are previous prototypes with half documented issues, mechanical constraints buried in CAD files, conversations with manufacturers about realistic tolerances, and internal notes on what worked and failed in past attempts. All of that context shapes the right design decisions, but it lives scattered across emails, Slack threads, CAD models, and memory.

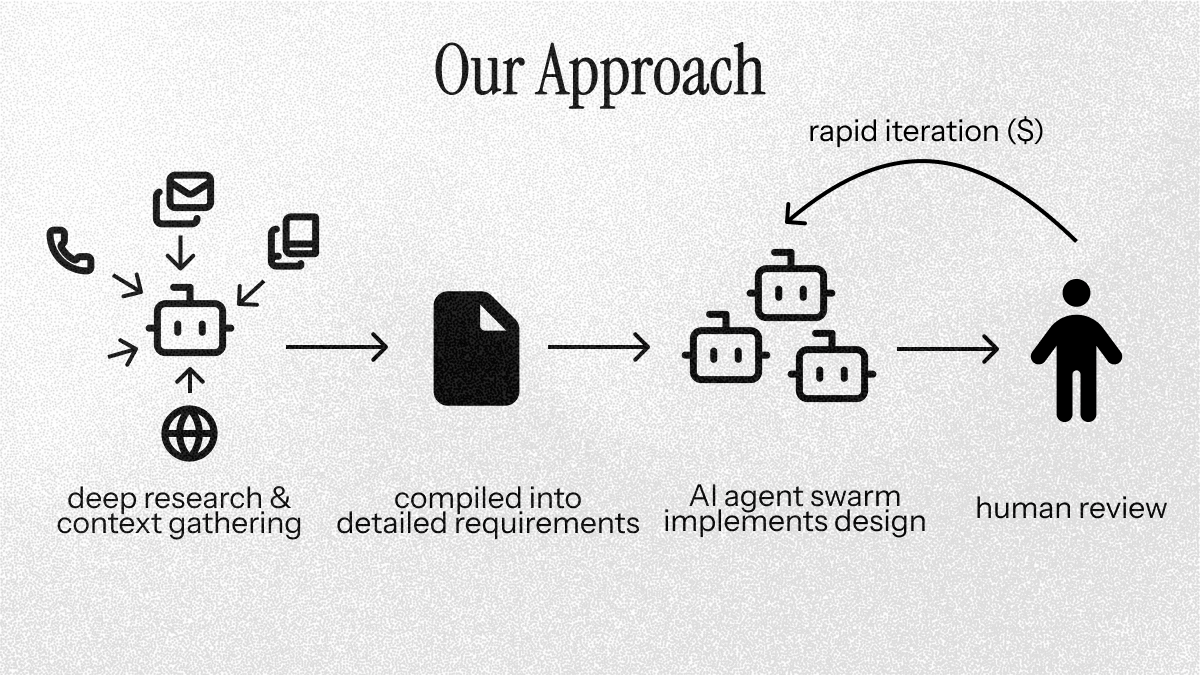

Our Approach

We flip that dynamic. Instead of waiting for you to hand us a perfect specification, we treat requirements capture as collaborative design work.

We ask targeted questions to surface unknowns early. What happens when the user unplugs USB mid-session? Does the enclosure allow side entry or top entry connectors? What is the real peak current, not just the average? How many units are you planning for the first run, and does that change component choices?

Those questions are not formalities. They directly shape which power IC to use, how to lay out the board, and what trade-offs to make between cost and capability. By resolving ambiguities during requirements rather than after layout, we avoid expensive redesigns and prototypes that technically work but do not fit the actual use case.

We use a research and planning agent to ingest your full project background. You can share call transcripts, previous schematics, mechanical drawings, email threads with suppliers, internal notes, and test reports. The agent processes all of that material and builds comprehensive understanding of your requirements, constraints, and goals. It surfaces the context that matters when making design decisions, so nothing important gets lost.

That means we are not starting from zero in a single kickoff call. We come to the design phase already aware of what you tried before, what failed, what worked, and what constraints you are navigating. The agent helps us ask better questions and catch potential mismatches before they become expensive mistakes.

The Solution: Five Days to Production Ready

When Fluid came to us, the goal was clear: unblock the product fast. They were willing to invest for speed, but only if the outcome was production worthy rather than another fragile prototype.

We committed to a concrete schedule: capture requirements, design the schematic, complete PCB layout, and hand off manufacturing ready files in five days.

Within that window, we:

- Replaced the earlier IP5310 approach with TI's BQ25185 power management IC, following datasheet layout guidance closely

- Cleaned up the user interface to a single logical BOOT and reset path for the RP2040

- Sized the board to fit within a 24 mm width and 50 mm length, with mounting holes exactly where the enclosure needed them

- Finalized connector strategy: USB-C for power and data, side entry Molex Picoblade for speakers, side entry JST PH for the battery

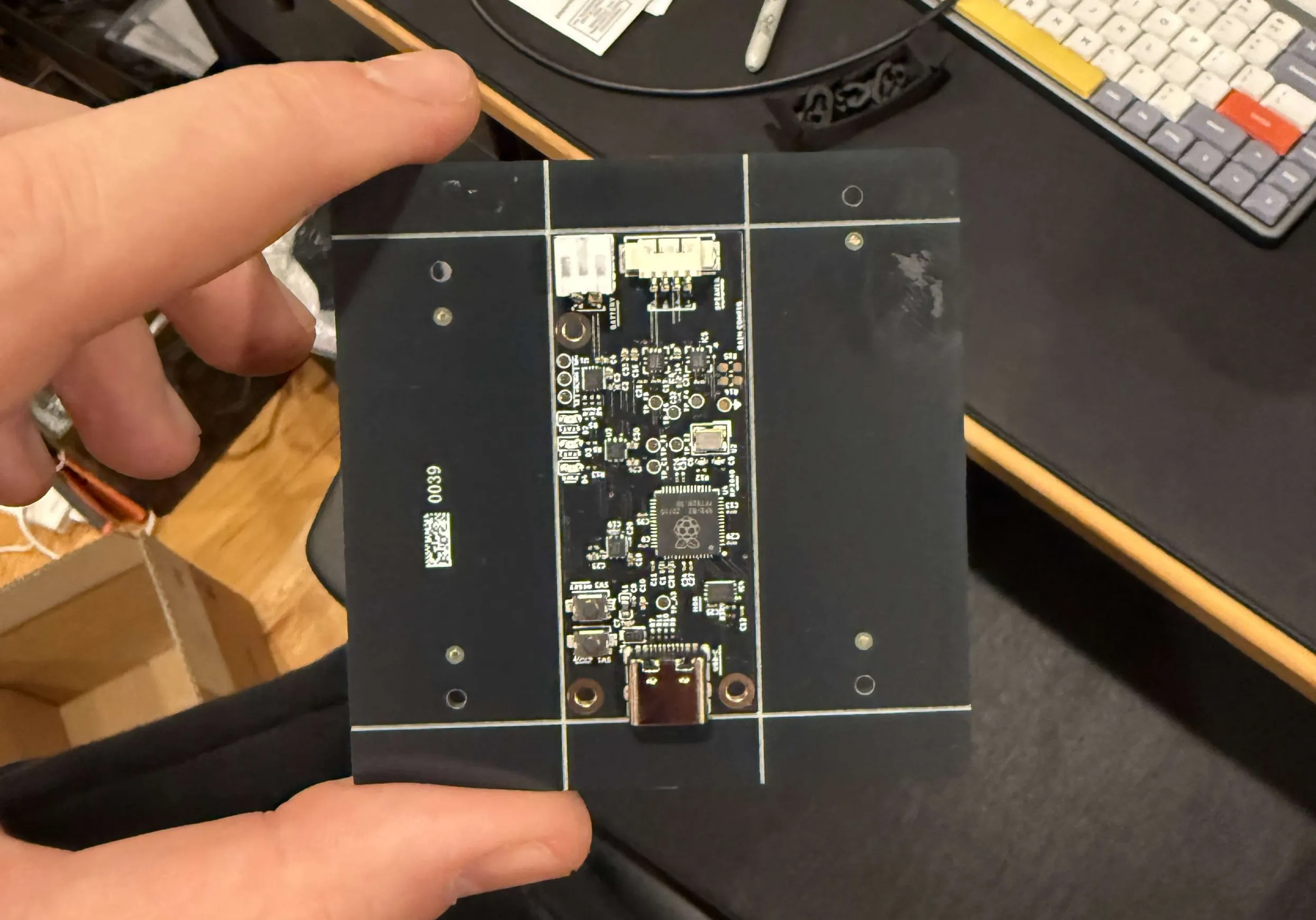

By the end of the week, Fluid had schematics, layout, Gerbers, and a BOM ready for JLCPCB. The first small run came back working and set the pattern for subsequent builds.

Results and Impact

From initial contact to shipping 200+ production units took weeks, not months. The Beyondex mod successfully delivered on its promise, giving Beyond VR headset owners the audio quality they wanted.

Every hardware project starts as a vision, something you want to exist in the world. Our goal is to remove the barriers between that vision and a real, shippable product. We want to help everyone turn their ideas into reality, whether you are a first-time founder with a napkin sketch or an experienced team scaling to production.

Ready to bring your hardware idea to life? Let's talk.